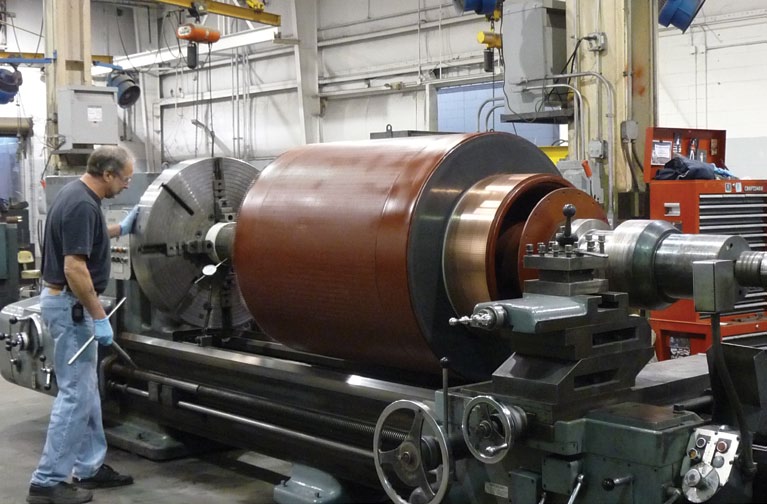

Machine Shop

Our machine shop has all the tools necessary to do a first class job. All incoming apparatus are disassembled and inspected both mechanically and electrically. Frequently, machine work and welding of critical parts is necessary for proper repair and reliable operation. Our machine shop includes a full range of lathes, horizontal and vertical mills, horizontal/vertical presses, broaching and inside key-cutting equipment. Welding services include tig, mig, and arc.

We have added some new tech instruments in the past few years that enables us to stay on top of maintenance procedures that are required on today's modern equipment and motors. For instance, we can now laser align motors or gearboxes as well as check for critical vibration problems with our Vibration Analysis equipment which is portable and allows us to do "on-site" tests and balancing.

Vibration Analysis

On site "Vibration Analysis and Laser Alignment" of critical equipment and components saves downtime and lowers cost. This is done by detecting equipment faults, most commonly detecting faults in rotating equipment (fans, motors, pumps, gearboxes, and etc). Faults such as unbalance, misalignment, rolling element bearing faults, and resonance conditions are easily identified through this method.

Experience

We have a dedicated crew containing members that have over 20 years of experience. This ensures that your motor will be repaired quickly, and more importantly, correctly. Our process guarantees efficiency, and our refusal to cut corners ensures quality.

Rome Electric Motor Works, Inc. | 36 Westside Industrial Blvd. NW Rome, GA 30165 | Ph: 706-232-4483